Why Choose XL Gold?

There are many reasons to consider XL Gold. Please see below for further information.

- 100% Made in Sheffield, England.

- Made from high quality 1.25% Carbon Steel for excellent durability.

- Titanium Nitride (TiN) Coating improves wear resistance and extends blade life.

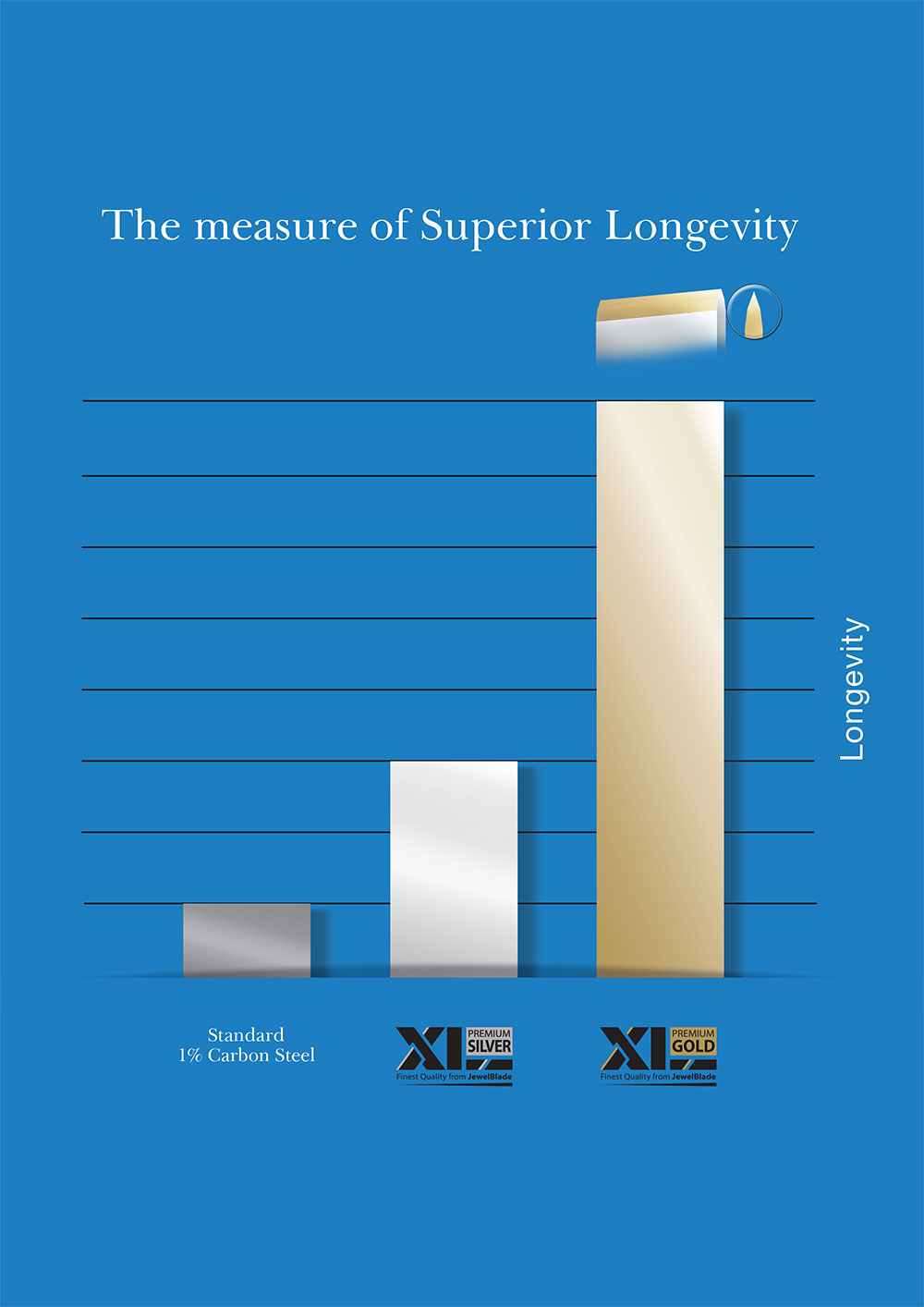

- Titanium Nitride (TiN) Coating can increase cutting performance by up to 8 x depending on the cutting media when compared to other conventional blades on the market.

- Ideal for use when cutting abrasive materials e.g. LVT, 6mm Plywood and Roofing Felt.

- Superior polished finish for increased slip factor and higher resistance to rusting.

- Fewer blade changes minimises tool downtime meaning that more time is spent on the job in hand, providing the user with a higher yield.

- Range of user friendly packaging available.

- Titanium Nitride (TiN) Coating is chemically very inert with high hardness and low friction combined with moderate resistance to oxidisation.

Achieve More with Less

Premium 1.25% Carbon Steel +Superior Manufacturing Capabilities + Titanium Nitride (TiN) Coating = Enhanced Longevity

Art & Science behind XL Premium Gold

- Finest high grade premium 1.25% Carbon Steel is assessed and evaluated by our steel specialists to ensure that it conforms to the Jewel Blade Quality Assured Standard.

- High Speed Performance Presses stamp the blades with the mark of quality ‘XL Premium’.

- Our unique specialised thermodynamic hardening and tempering heat treatment process, transforms the steel's microstructural atom properties, manifesting in a consistent hardened metallurgical structure.

- Utilising the latest grinding technology ensures honed precision cutting edge geometry.

- Surface finishing optimises cutting performance for the user's benefit providing higher productivity yields.

- Titanium Nitride (TiN) coating is applied to the blade's cutting edge through the vacuum process electron beam Physical Vapour Deposition (PVD) increasing the thickness and durability of the blades cutting edge thus ensuring extended blade life.

Technical expertise along with innovative high level intelligence testing solutions ensures that the steel characteristics and blade edge geometries are analysed and monitored throughout Jewel’s complex manufacturing processes. This guarantees a consistent molecular structure and enhanced cutting performance which will last longer even when cutting through the toughest of modern day materials.

Introducing Our Blade Designs

The XL Premium Gold range is available for various cutting applications with a wide choice of blade designs available to suit your specific industry sector and cutting task.

If you are unable to find a suitable blade from the range illustrated or require any advice on our bespoke design service, please contact our experienced team for further advice.

Straight Utility Blades:

Our range of Straight Trapezoidal Trimming Knife blades are designed to fit various professional Knives & Cutters. With a precision honed edge for consistent and long cutting life, these blades are ideal for use in multiple industries including Flooring, Roofing, Construction & Building, Joinery, Automotive interior components, Gardening and many more.

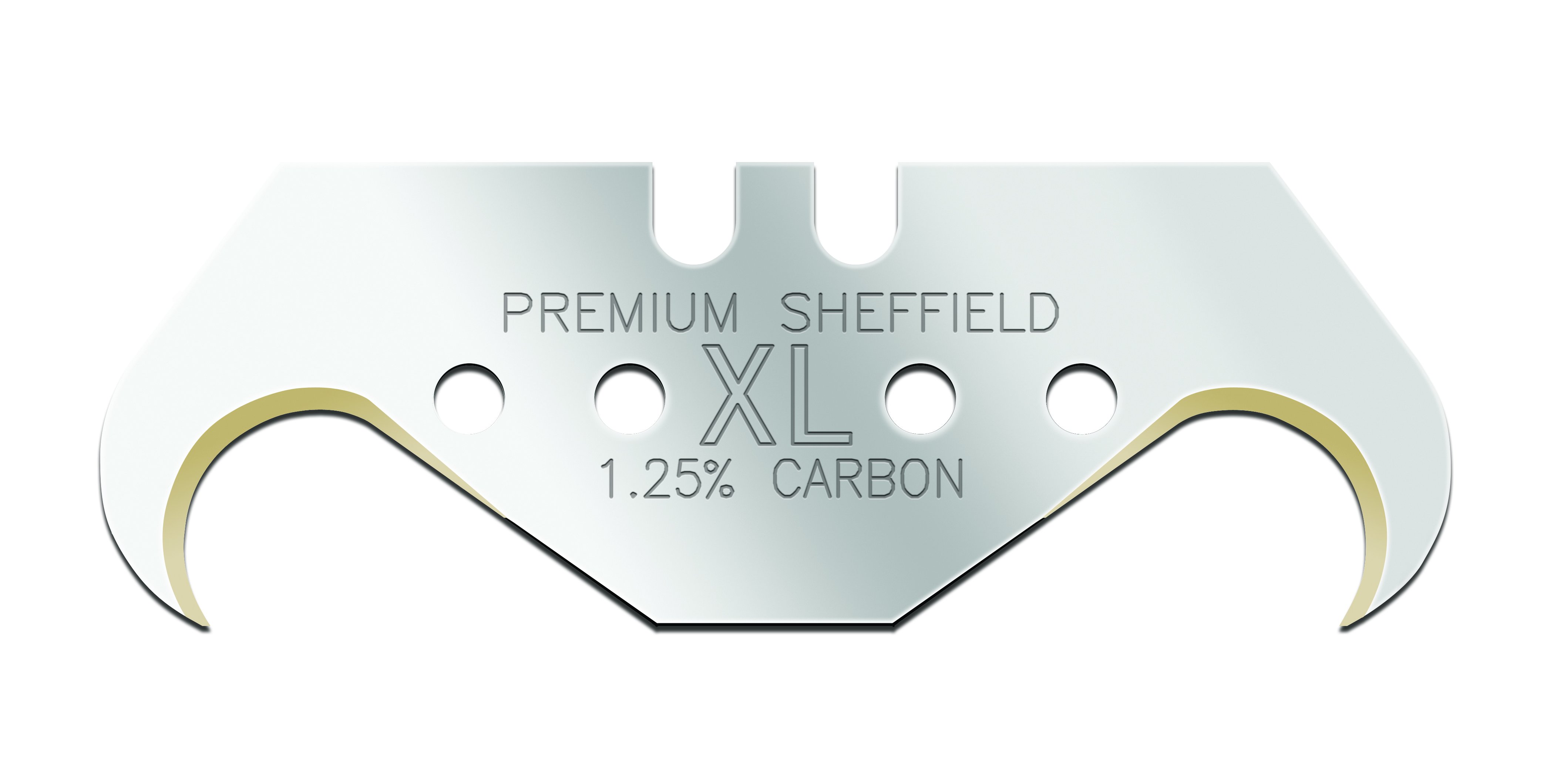

Hook Blades:

Our diverse range of Hook Trimming Knife blades are ideal for use in various industrial sectors including Roofing, Flooring and Textiles, providing the user with the ability to cut without damaging the contents beneath. Versatile blade designs to suit various cutting tools, professional knives and cutters.

Concave Blades:

Our range of Concave Trimming Knife blades are perfect for precision control when cutting and scoring various materials including LVT, 6mm Plywood, leather, wood, composite aluminium sheeting and craft materials. Our Concave blades are the ideal cutting solution where increased accuracy is paramount.

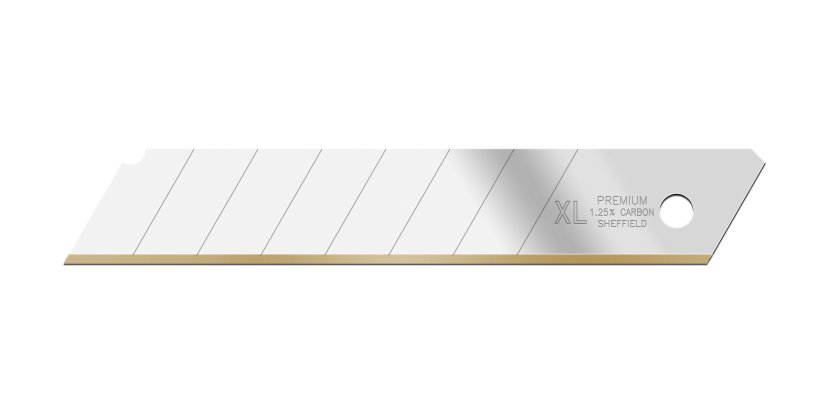

Snap Off Blades:

Our 9mm & 18mm Snap Off Trimming Knife blades are ideal for the professional tradesmen or DIY market and are designed to fit various professional snap off knives and cutters. With either 8 or 13 breakaway/snap cutting segments depending on your choice, our Snap Off blades are excellent for use in various industries including Automotive, Decorating, DIY, Flooring, Jewellery, Roofing and Textiles.

Non-Segmental Blades:

Our 9mm & 18mm Non-Segmented Trimming Knife blades are ideal for industrial applications and designed to fit various professional knives and cutters. The perfect cutting solution for use in the Automotive, Glazing, Decorating, Films and Packaging Industries.

Insulation Blades:

Our Insulation blades are available in a range of sizes consisting of 100mm, 130mm, 150mm & 160mm in length to suit individual preference and specific cutting requirements. Utilised predominantly in the Building & Construction Industry, these blades are perfect for cutting Plasterboard, Insulation materials and much more. Designed to fit most professional knives and cutters.

XL Gold Packaging Options

Trade/End User

- Poly/Cellophane wraps of 5 Blades, 100 Blades Per Box

- VCI Paper Wraps of 5 Blades, 100 Blades Per Plastic Reusable Box

- Safety Dispensers of 10 Blades, 100 Blades Per Box

- Plastic Tube of 10 Blades, 100 Blades Per Box

- Safety Dispensers of 10 Blades with Hanging Loop, 100 Blades Per Box

- Plastic Hanging Tubes of 10 Blades, 100 Blades Per Box

Retail

- Clear Blister on a Retail Hanging Card, 20 Cards Per Box. Available in 5 or 10 Blades

- Safety Dispenser on a Blister Retail Hanging Card, 20 Cards Per Box. Available in 5 or 10 Blades

- Plastic Tube of 10 Blades on a Blister Retail Hanging Card, 20 Cards Per Box

- Safety Dispenser of 10 Blades with Hanging Loop on a Blister Retail Card, 20 Cards Per Box

XL Premium Gold Case Studies / User Experiences

Paul Finch NICF Master Fitter

"The XL Premium Gold Concave blades are ideal for use on Heavy Duty LVT. This is where it becomes more evident that the blades are longer lasting."

David Russell Curriculum Manager at CP Assessments

"The XL Premium Gold blades worked amazingly well on LVT and Resilient Safety Flooring."

Steve Ramsden Master Fitter and President of NICF – National Institute of Carpet & Floorlayers. Trainer at FITA – Flooring Industry Training Association

"The XL Premium Gold Concave blades are superb when cutting 6mm Plywood; they keep their tip and edge really well in comparison to the standard blades. With the XL Premium Gold, you can template a normal sized bathroom with just one blade in comparison to using 4 - 5 standard blades for the same job. This saves me time from a tool downtime perspective and makes blade disposal easier and safer."

“You can immediately feel the difference between the standard blades and the XL Premium Gold.”

David Russell, CP Assessments

XL Premium Gold Q&A

- How is the TiN coating applied to your XL Premium Gold blades?

- The Titanium Nitride (TiN) coating is applied by Physical Vapour Deposition (PVD). Our blades are jigged in a chamber for coating and it is applied through the process of electron beam evaporation under vacuum at a workpiece temperature of below 500°C. This method results in a very smooth coating which does not require any further finishing. The ceramic coating is a bright gold metallic colour in appearance and the thickness is geometry dependant at 1 - 4 microns.

- How does the TiN coating work to extend blade life?

- Titanium Nitride (TiN) reduces the coefficient of friction and therefore decreases the rate of blade edge deterioration. Another characteristic of the coating is that it increases the blades resistance to corrosion as it is chemically very inert.

- Hi I am a floor layer and just wanted to know. On what materials will I most benefit using your XL Premium Gold blades?

-

The XL Premium Gold blades have been designed and developed to provide the user with a longer lasting cutting edge which is ideal for use on materials where you find yourself with either increased breaking or blunting of your existing blades.

- Resilient Flooring & LVT

- 6mm Plywood

- Heavy Duty Safety Vinyl Flooring

- Artificial Turf

XL Premium Gold blades are also recommended for use on some of the materials listed below.

- Ideal for use on materials containing Carborundum/Silicon Carbide.

- Engineered Wood

- Rubber Matting (Gym Flooring)

- Rubber Seals/Tubing

- Plasterboard

- Bitumen Felt Roof Shingles

- Will the cutting sensation be different to a standard non coated blade?

- The cutting sensation you will experience will be entirely dependent on the cutting media, however the first time you use the XL Premium Gold you may get a slightly different feel, as although the TiN coating is very smooth, it does increase the thickness and robustness of the blade's cutting edge. Therefore your initial point of contact may provide you with a different cutting sensation. What you may potentially find is as the coating's properties work to protect the blade cutting edge, that the blade will start to feel keener over its extended life span.

Sales & Distributor Enquiries

Please complete the following contact form and our sales team will call you back!